Cylinder Head Skimming in Sutton & Its Surrounds | SRS Engineering

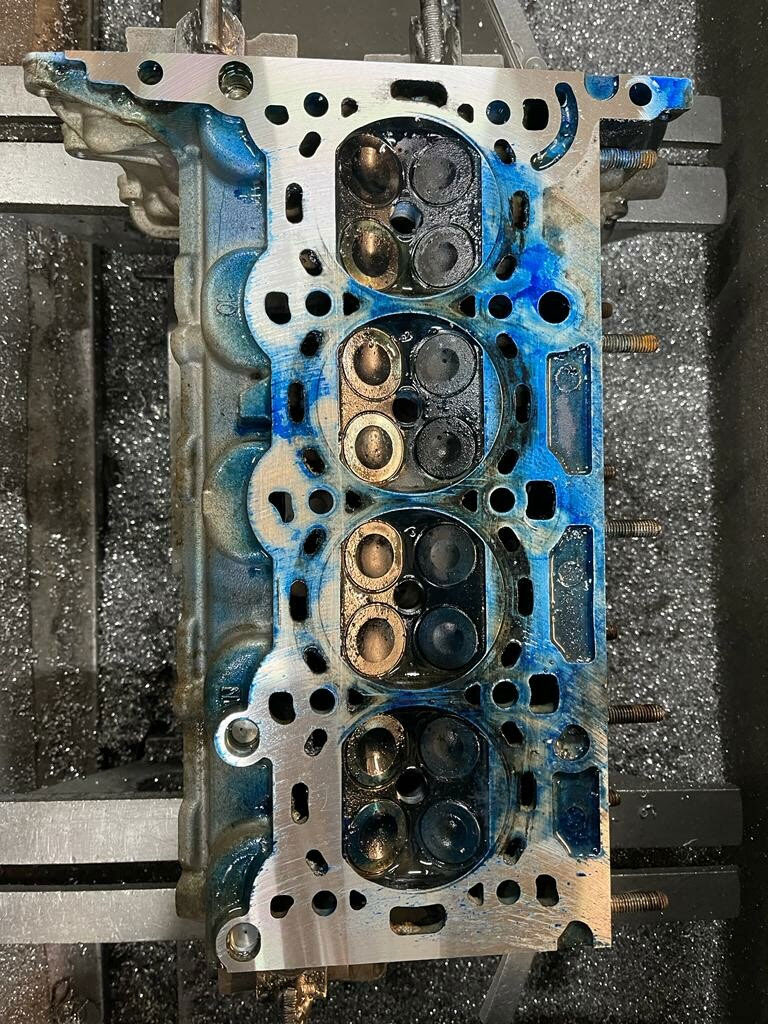

After an engine overheats, blows a gasket, or begins to suffer the effects of corrosion, you may be left with distorted cylinder heads that could cause engine malfunction. You’re also more likely to experience premature gasket failure. In cases like these, we recommend cylinder head skimming to restore the correct surface finish.

Our Sutton based workshop specialises in this service, and extends it to motorists, trade clients and main dealers throughout nearby areas like Croydon, Epsom, Kingston, Streatham and Wimbledon. The SRS Engineering team uses the latest equipment to run speedy, accurate diagnostics, before making suggestions on the best course of action for you. If it is indeed cylinder head skimming that’s the best option, it’ll be undertaken to the highest possible quality standards, ensuring precise surface levels.

Cylinder Head Skimming Explained

Cylinder head skimming involves removing a thin layer of metal from the surface of the engine's cylinder head to create a smooth and flat surface. This is done to ensure proper sealing of the head gasket and to restore the head's geometry to its original specifications, following some kind of engine difficulty such as a blown gasket, overheating or corrosion. It’s not typically offered at generic, MOT style garages around Croydon, Epsom, Kingston, Streatham and Wimbledon, so you’ll need to visit a specialist workshop like ours in Sutton.

It involves using a specialised instrument called a head skimmer to shave off the metal surface of the cylinder head. The amount of metal removed during the process is typically small, and is carefully monitored to ensure that the head remains within its tolerances. Cylinder head skimming can improve engine performance and prevent leaks, but it should only be done by a qualified technician using proper equipment – an amateurish job can have the exact opposite effect you’re looking for.

It’s often offered as part of gasket repairs, due to the co-morbidity of blown gaskets and cylinder head warping. Cylinder head pressure testing – which we also offer as a standalone service – is always carried out before we proceed. This will help identify any cracks or leaks not visible to the naked eye.

Step-by-Step:

- We remove the cylinder head then check its flatness

- If distorted, we’ll skim the surface using a fly cutting method, taking off a carefully pre-determined layer of surface metal

- The aim here is to take off as little material as possible, ridding it of distortions without overly-impacting compression levels

- Following the completion of cylinder head skimming, we may be required to resurface valves and valve seats to amend their depth

- We then test the cylinder heads to ensure they’re perfectly flat

- Once we’re confident the engine has been restored to full functionality, you’re good to go

- This is part of our commitment to your peace of mind – and why our Sutton workshop proves so popular with motorists, trades and dealers around Croydon, Epsom, Kingston, Streatham and Wimbledon